Everything that you need. All under one roof.

SAMARIUM-CO SOLUTIONS

We supply Samarium Cobalt in forms like discs, blocks, rings, and segments, designed for aerospace, military, and high-temperature applications. Our global supply chain offers exceptional magnetic stability and corrosion resistance, ensuring reliable performance in extreme conditions.

SPECIFICATIONS

Chemical Composition: Samarium-Cobalt (SmCo) alloy, with Samarium and Cobalt in ratios like SmCo5 or Sm2Co17, enhanced with Iron and Copper for optimized strength.

Forms:

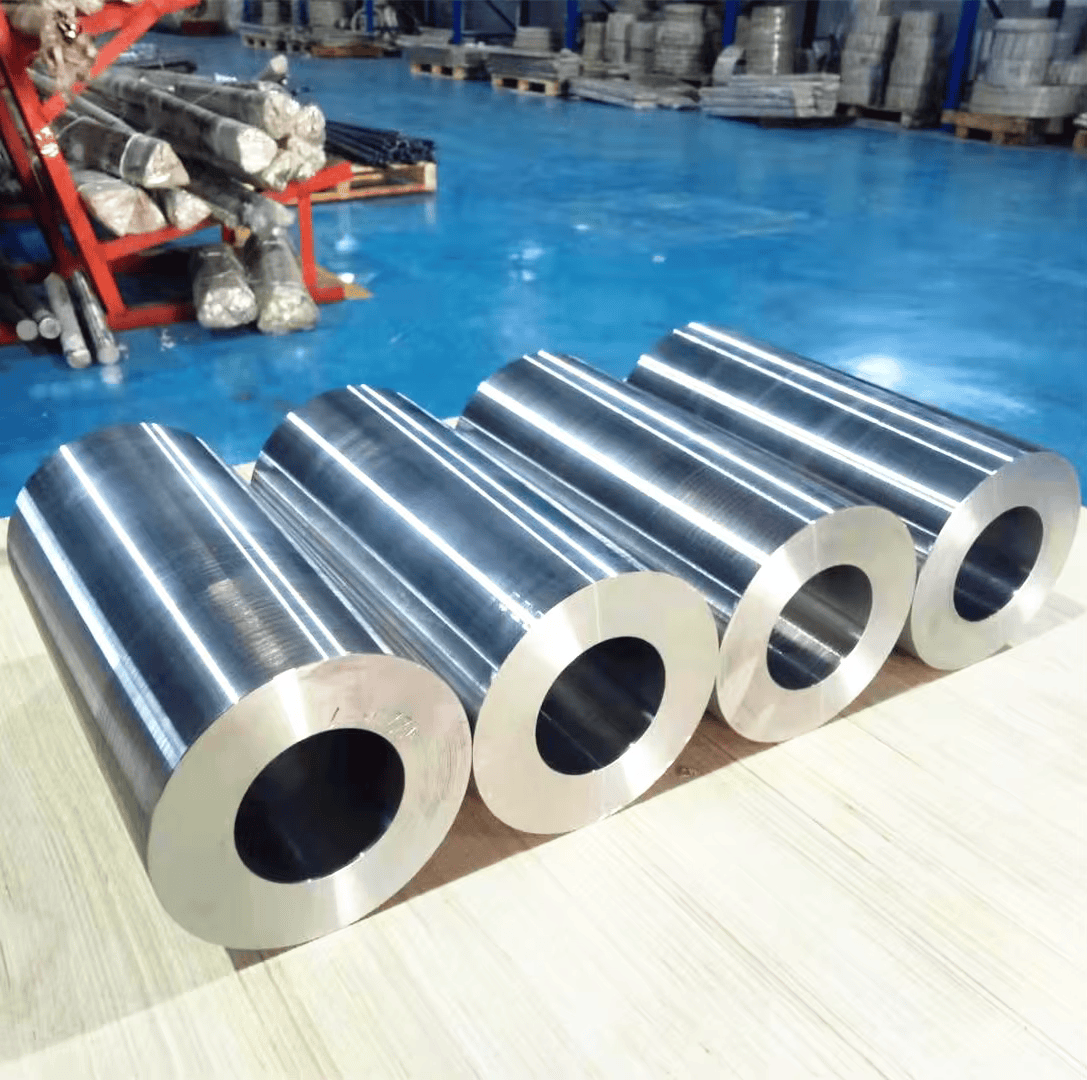

Discs: Circular magnets for sensors and actuators.

Blocks: Rectangular magnets for generators and magnets.

Rings: Hollow magnets for magnetic bearings.

Segments: Wedge-shaped magnets for motors and turbines.

Weights:

Discs: 0.01-4 kg per magnet.

Blocks: 0.05-8 kg per magnet.

Rings: 0.02-6 kg per magnet.

Segments: 0.03-7 kg per magnet.

Grades:

SmCo5: First-generation alloy for moderate strength and high resistance.

Sm2Co17: Second-generation alloy for superior temperature stability up to 350°C.

Coatings:

Nickel (Ni): Basic corrosion protection for general use.

Gold (Au): Premium coating for medical and aerospace applications.

Epoxy Resin: Enhanced durability for harsh environments.

Uncoated: Raw option for specific industrial processes.

Sizes:

Discs: 2-80mm diameter, 0.5-40mm thickness.

Blocks: 5-150mm length, 5-120mm width, 1-40mm thickness.

Rings: 10-120mm outer diameter, 5-90mm inner diameter, 1-30mm thickness.

Segments: 15-150° angles, 10-100mm radius, 1-25mm thickness.

Certificates:

RoHS Compliance: Ensures no hazardous substances, safe for electronics and EU markets.

ISO 9001: Guarantees consistent quality management throughout production.

EN 10204 3.1: Confirms compliance with order specs, backed by independent test results.