Everything that you need. All under one roof.

MONOCRYSTALLINE-SI SOLUTIONS

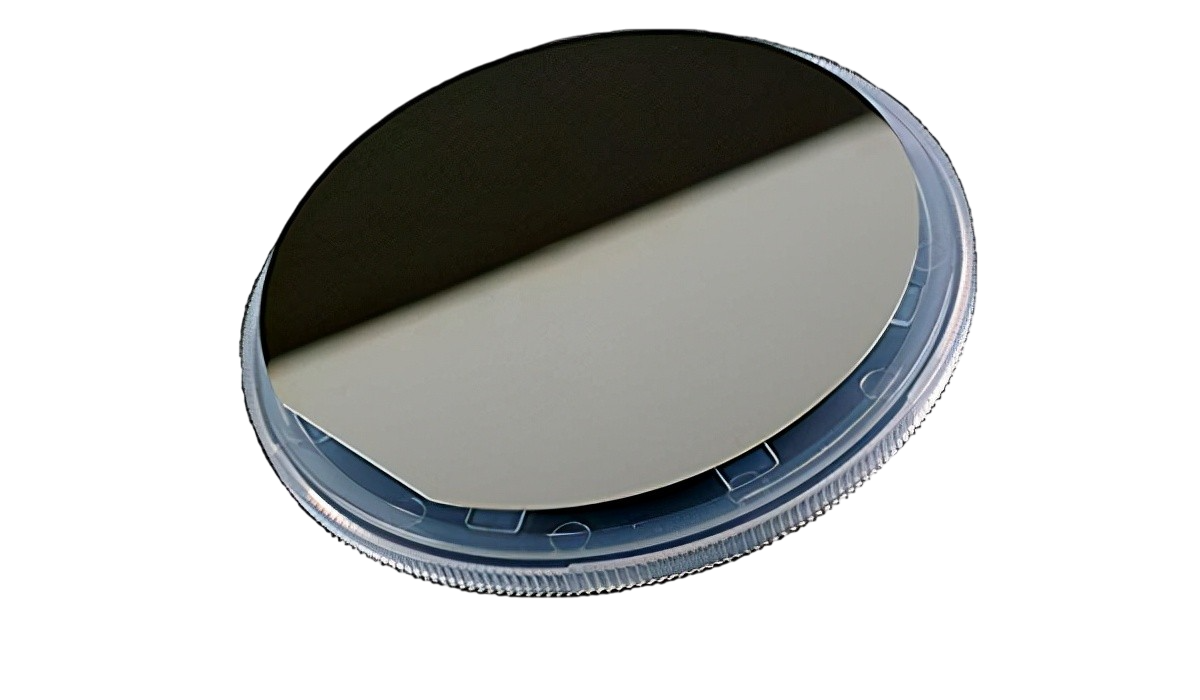

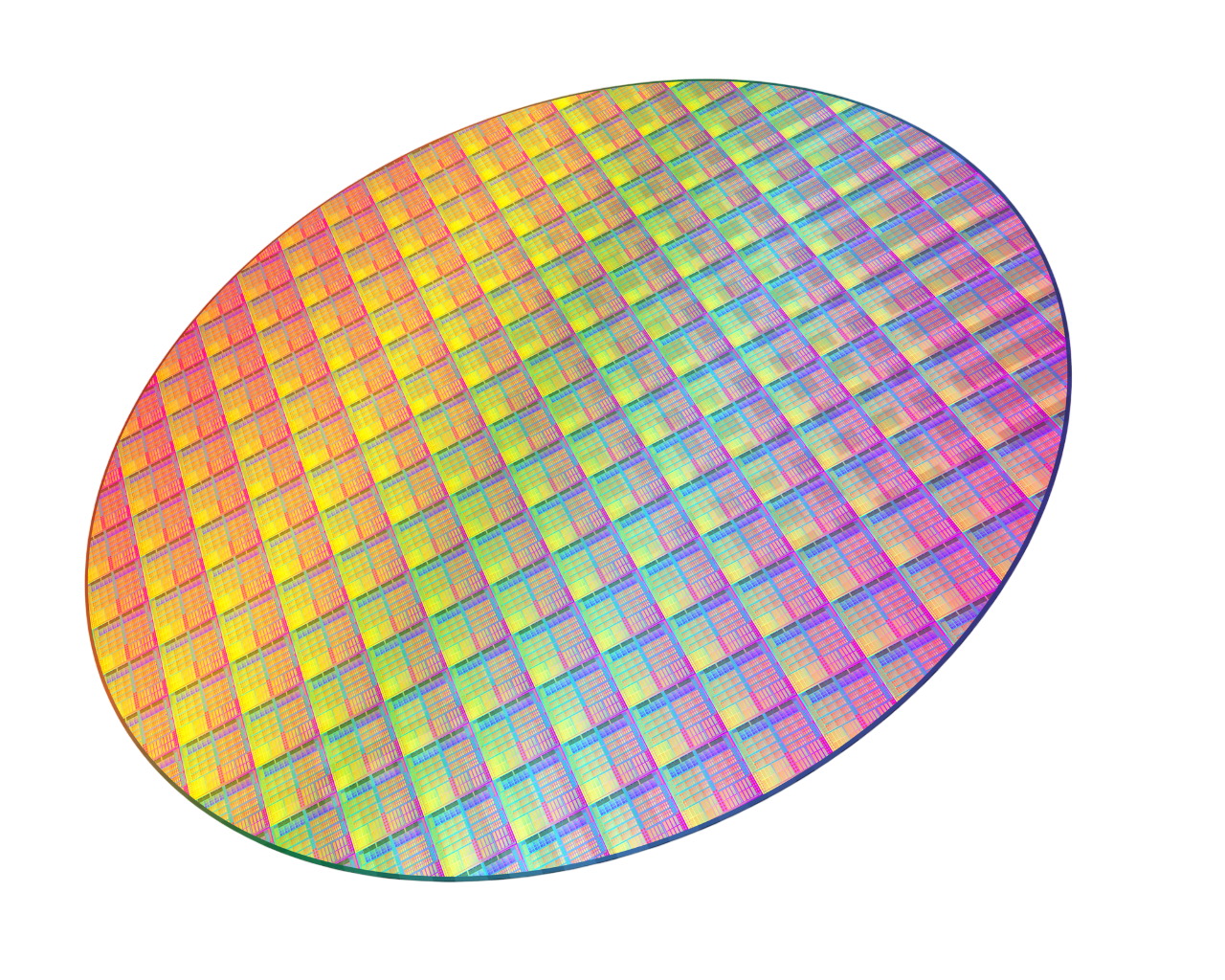

We supply Monocrystalline Silicon in forms like ingots, wafers, rods, and slices, designed for high-efficiency solar cells, advanced electronics, and semiconductor manufacturing. Our global supply chain offers premium purity and structural integrity, ensuring top-tier performance and reliability.

SPECIFICATIONS

Chemical Composition: Monocrystalline Silicon (mono-Si), a single-crystal form of silicon grown via the Czochralski process, with minimal impurities for optimal conductivity.

Forms:

Ingots: Large single crystals for wafer production.

Wafers: Thin discs for solar cells and chips.

Rods: Cylindrical forms for research and cutting.

Slices: Pre-cut pieces for immediate use.

Weights:

Ingots: 20-150 kg per unit.

Wafers: 0.01-0.7 kg per batch.

Rods: 0.1-5 kg per rod.

Slices: 0.05-2 kg per unit.

Purity Levels:

6N (99.9999%): Standard purity for solar-grade silicon.

7N (99.99999%): High purity for electronics.

8N (99.999999%): Ultra-pure for advanced semiconductors.

9N (99.9999999%): Maximum purity for niche applications.

Doping Types:

Boron-Doped (p-type): For positive charge carriers.

Phosphorus-Doped (n-type): For negative charge carriers.

Undoped: Raw silicon for custom doping.

Arsenic-Doped (n-type): Enhanced conductivity for specific uses.

Sizes:

Ingots: 150-300mm diameter, 100-600mm length.

Wafers: 100-300mm diameter, 0.1-1.5mm thickness.

Rods: 10-50mm diameter, 50-300mm length.

Slices: 100-300mm width, 100-300mm length, 0.5-2mm thickness.

Certificates:

RoHS Compliance: Ensures no hazardous substances, safe for electronics and EU markets.

ISO 9001: Guarantees consistent quality management throughout production.

EN 10204 3.1: Confirms compliance with order specs, backed by independent test results.