Everything that you need. All under one roof.

CORDIERITE SOLUTIONS

We supply Cordierite in forms like powders, ceramics, components, and grains, designed for automotive catalytic converters, refractory linings, and high-temperature applications. Our global supply chain offers exceptional thermal shock resistance and low thermal expansion, ensuring durable and efficient performance.

SPECIFICATIONS

Chemical Composition: Cordierite (2MgO·2Al₂O₃·5SiO₂), a magnesium aluminosilicate, with minor additives (e.g., talc, kaolin) for enhanced thermal stability and formability.

Forms:

Powders: Fine particles for ceramic production and additives.

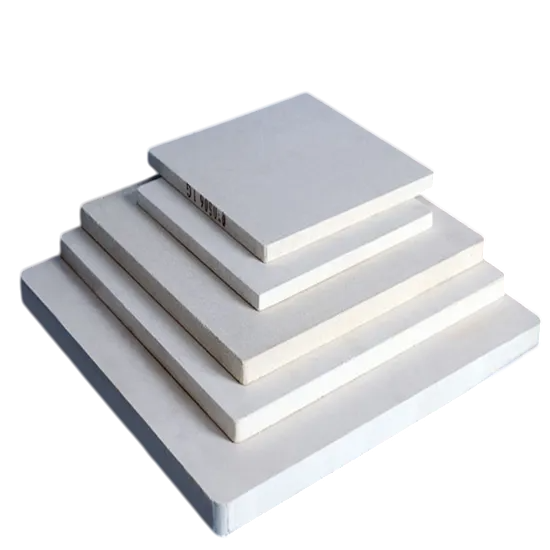

Ceramics: Sintered components for catalytic converters and kiln furniture.

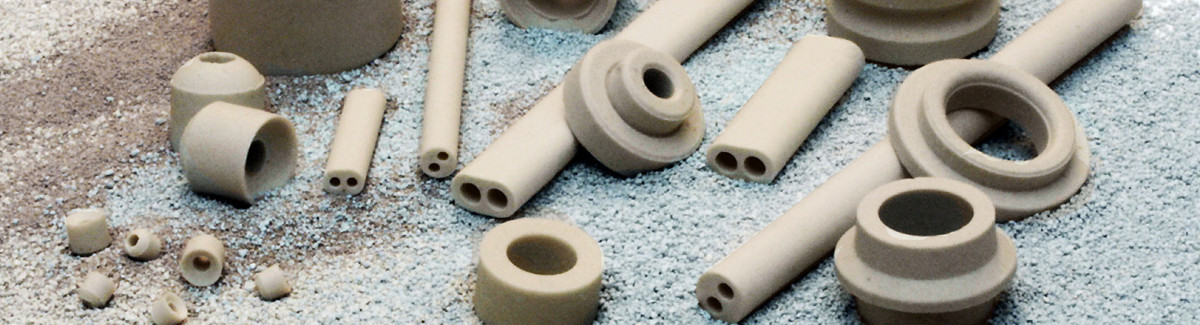

Components: Shaped parts for industrial and refractory applications.

Grains: Granular forms for abrasives and high-temperature linings.

Weights:

Powders: 25–300 kg per bag.

Ceramics: 0.5–25 kg per unit.

Components: 0.1–10 kg per batch.

Grains: 10–100 kg per unit.

Purity Levels:

92%: Standard purity for industrial ceramics and refractories.

95%: High purity for automotive catalytic converters.

98%: Ultra-pure for high-performance kiln furniture.

99%: Maximum purity for specialized industrial applications.

Mechanical Properties:

Hardness: 7–8 Mohs, suitable for durable refractory components.

Compressive Strength: 100–300 MPa, ideal for high-stress industrial uses.

Thermal Shock Resistance: Up to 500°C ΔT, ensuring stability in rapid temperature changes.

Thermal Conductivity: 1–3 W/m·K, supporting heat resistance in automotive and refractory applications.

Sizes:

Powders: 0.1–150 microns particle size.

Ceramics: 50–200 mm diameter, 10–100 mm thickness.

Components: 10–150 mm length, 5–80 mm width.

Grains: 0.5–10 mm particle size.

Certificates:

RoHS Compliance: Ensures no hazardous substances, safe for electronics and EU markets.

ISO 9001: Guarantees consistent quality management throughout production.

EN 10204 3.1: Confirms compliance with order specs, backed by independent test results.